|

- Helmholtz Coils -

Comments on aspects of design of the BH300/600/1300

family

In

general:

It was looked for simplicity and robustness

with the smaller weight, with the possibility of modifying the

configuration of the coils to obtain a great versatility. Serviciencia

started to produce coils with these features on 2005.

The

support:

We have devised the system of 4 pillars fixed to a

lower plate and another

upper one. The coils are fixed with special

fork brackets screwed to the

pillars.

This

system provides firmness to the set and great facility to place the

device under study at the centre of the coils, being also relatively easy its

assembly and its possible disassembly. The same support is used for the

three versions of each size (one, two or three axes).

The inferior plate also makes of table to help to place the object

under study, or the necessary instruments, in the coils (the plate has a threaded

hole at its centre). Also it serves to locate the wiring channels and the connection terminal

block for the pairs of coils.

The superior plate has a circular window to allow the passage of objects towards the

centre of the

coils. This plate can be removed if it were necessary, without harming too much

the rigidity of the set (excepting for the one axis versions). Also it can be replaced by another plate

done

specially for some application in particular.

The plates are of foamed PVC, with a density similar to the one of the

softwood, reason why they are easy to drill or to cut if it is necessary.

The

connections:

Each single coil of a pair has its own

terminal block with nuts to

hold the terminals of connection cables. This makes possible to modify the

connections in each coil as wanted and with enough easiness. An example

would be

the "anti-Helmholtz" set-up, to generate gradients instead of homogeneous

fields (see a comment in below about this applied to the forms).

The

forms (or bobbins):

We

developed specific techniques to curve "U" shaped profiles in very

precise circles and to accommodate the winding in its channel. We use

profiles of an aluminium alloy because they don't distort the magnetic

field, don't need exterior finishing coating and for being light but with a

suitable mechanical rigidity.

Under these premises we obtain coils with a cross-sectional area the smaller

as possible in practice, which results in a better access to its interior, among

other benefits.

These forms provide an optimal evacuation of the heat generated by the

electric current, which makes possible a relatively high current

density in the windings.

The concept "In-Circuit

Coils Forms":

We think that this is a feature unique to our

Helmholtz coils (1)(Footnote), put

into practise with the aim to obtain a maximum versatility of the sets.

The basic idea is to use also the aluminium forms like coils. It is a

logical consequence of the fact that each one of these circular forms must

have its ends electrically separated in order that does not behave

like a short-circuited

loop when the coil works with alternating current.

Therefore each form constitutes a coil of a single turn. We have made the connections between the two

of each pair and between these and the general

connection block.

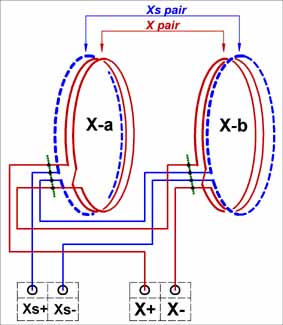

This way we obtain an "extra" Helmholtz pair in each axis (denominated with

the suffix "s" after the letter of the axis). The following simplified

scheme shows the standard connection of pair X. For axes Y and

Z it is

applied the same.

We call Xs the pair formed by the

forms of pair X. In the same way exist Ys and

Zs. X-a and X-b are the two coils of pair X.

Applications of

"In-Circuit Coils Forms":

At the moment we conceive two basic applications:

like electrostatic screens and for generating small special fields.

Like electrostatic screens when, for example, the coils are used like sensors

of magnetic flux in the measurement of the magnetization, or the magnetic

moment, of

some magnet or another magnetized piece. A proper connection of the forms could

diminish the electrical noise remarkably when the signal is very low.

The wiring in between the two forms of a pair contributes to keep these at

same potential, what is very useful in applications at high frequencies,

because helps to diminish the generated electrical field, which is

normally unwanted due to the possible capacitive coupling with the DUT.

Noteworthy, the generated electric field increases with frequency.

But more interesting they seem, nevertheless, for field generation, for which we

suggest the following two applications.

First is the generation of a secondary homogeneous field to modulate the

main field, by means of a source of current different from the one for

the main pair.

Second it is the generation of small magnetic gradients to improve the homogeneity

of the main field when it is tried, for example, to cancel the

terrestrial magnetic field in a very high degree. This could be necessary

due to gradients in the local field produced by the influence of

neighbouring

ferromagnetic masses, such as structures of the building, machinery, terrain

features, etc.

Also it can be useful for some experiment in particular that needs a

main field with a superposed gradient, static or variable.

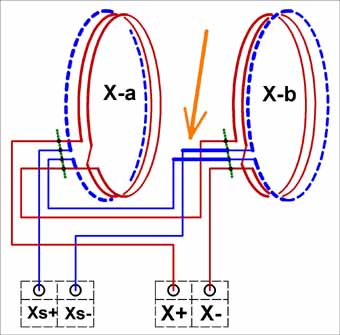

In order to generate a gradient with a pair of coils these must be connected

of the

way that usually is called "anti-Helmholtz". In the following figure we show the

same former Xs forms pair connected in this way.

The arrow indicates the modified connections,

drawn up in

heavier blue lines. Comparing this scheme with the previous one aids to notice better the difference "Helmholtz / anti-Helmholtz".

We trust that the users will be able to find other utilities to this

feature of our coils. We will be delighted in to know about this.

Updated:

30-Nov-2022

|